Why Protective Cannabis Packaging is Your Sustainability Breakthrough

In an industry with serious sustainability challenges, Calyx stands out by optimizing packaging performance and materials to make your brand sustainable to the core. We're comparing the product preservation and sustainability benefits of options like hermetically sealed packaging and Biophotonic glass to show that packaging specifically designed for cannabis offers the ideal balance of shelf life and environmental responsibility.

Stay in touch!

Join our email list to receive Calyx content & product updates.

By Nicole Erickson + Tobe Nightengale in Cannabis Packaging

Quick Hits

- Product degradation and spoilage contribute to the cannabis industry’s significant waste problem, but can be mitigated by thoughtfully selecting advanced, protective packaging.

- Hermetically sealed packaging provides impressive initial product protection, but can’t be resealed once it’s been opened. This effectively renders it single-use, which isn’t practical for the average cannabis consumer or a sustainable choice for your business.

- Biophotonic glass packaging has strong UV-blocking capabilities, but offers minimal shelf life benefits compared to its high price and reliance on emissions-heavy international supply chains.

- Calyx’s USA-made Drams and three performance tiers of Concentrate Containers offer up to 6.5x greater resistance to environmental changes through our proprietary resealable closure, sustainably keeping your products in ideal conditions.

Preserving Cannabis Products Protects Our Planet

The modern cannabis industry emits approximately 3,000 metric tons of carbon for every metric ton of cannabis produced. That’s around 85 kg of carbon per ounce of cannabis flower. Every gram of unprotected, degraded product represents harm to our planet in the form of energy and resource waste.

Calyx’s focus on product preservation is, in part, motivated by our desire to eliminate waste at the source by providing cannabis packaging with superior protective qualities when compared to alternatives. We infuse our quality and sustainability values into high performing packaging designs and mindful manufacturing processes to ensure that the energy and resources your team puts into cultivation and processing are retained all the way through to your end consumer’s experience.

Product Testing for a Sustainable Supply Chain

Mitigating Mold through Moisture Testing

Uncontrolled moisture loss or gain can be detrimental to your cannabis products. Too little moisture and cannabinoids and terpenes will quickly degrade. Too much, and the risk of mold or microbial growth goes up exponentially.

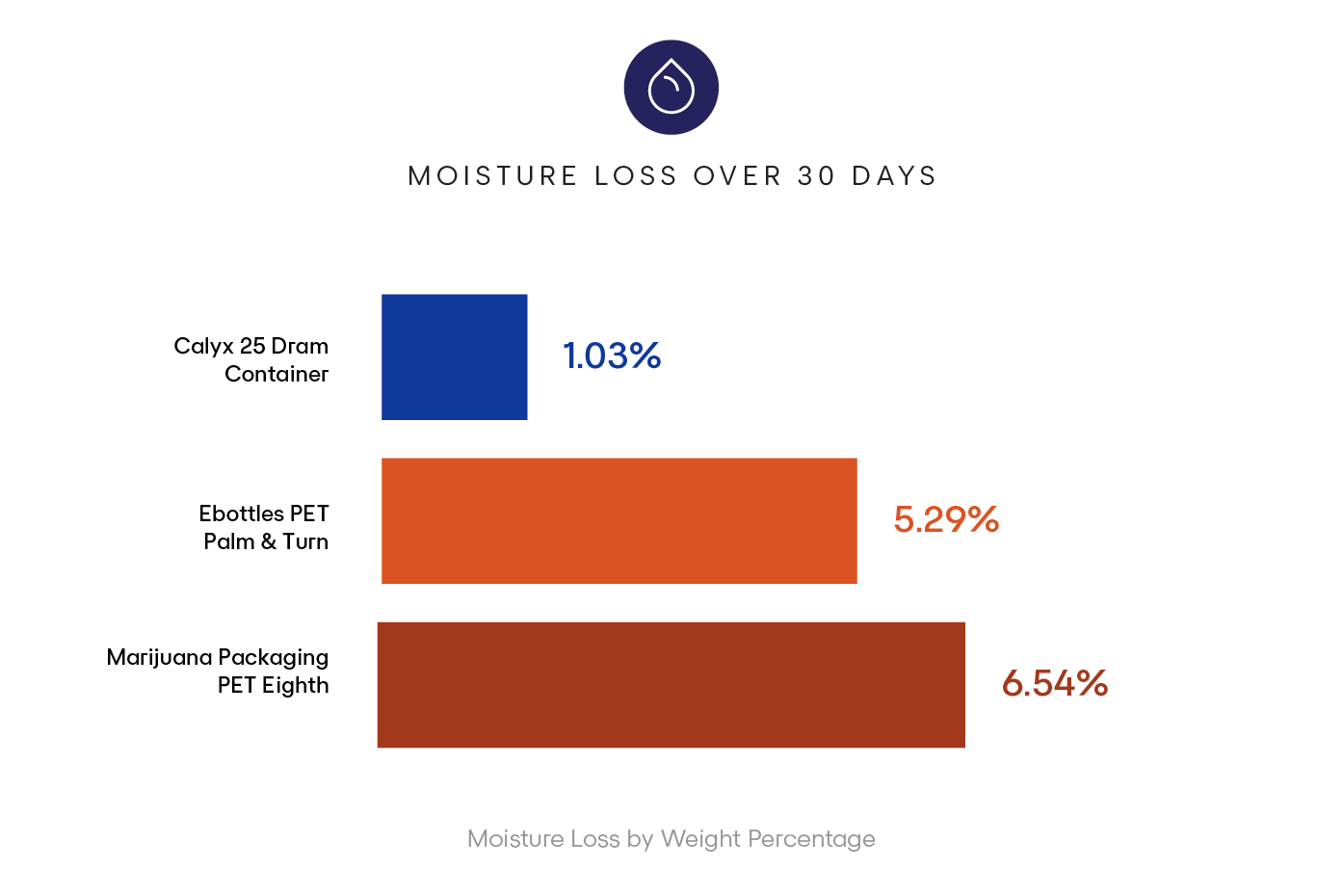

Moisture Vapor Transmission Rate (MVTR) Testing is one of many methods we utilize to understand how well a package might perform with cannabis, with Calyx Plastic Drams and Concentrates specifically engineered to control moisture and humidity better than our competitors. We’ve found that Calyx Drams retain and resist change in moisture up to 6.5x better than common competitors, offering a massive advantage to your product’s shelf life. Whether you are in a dry or humid environment, you can rest assured that Calyx will keep products safe and secure while eliminating harmful waste from your business’ environmental footprint.

Keep Terpenes Fresh through Superior Concentrate Packaging Design + Materials

Heat, oxygen, and UV light are all enemies of cannabinoids, but terps are another beast, and understanding their characteristics can help you choose protective, sustainable packaging.

Your choice of packaging is especially important when considering terpene-rich concentrates, given that a low quality jar will allow the vast majority of volatile organic compounds to degrade in only a few weeks. This rapid terpene loss renders your product lower quality than intended, or worse, unusable, contributing to the cannabis industry’s waste problem.

Terpenes are not particularly reactive to O2 and UV, and terpene loss is primarily driven by seal quality and material selection. Terps are powerful solvents with the ability to degrade most common plastics and rubbers. In a head-to-head study, we found that many “high-performance” concentrate containers didn’t hold up to terpene exposure and experienced significant terpene loss over just a few days. Calyx Concentrate Containers are built differently–we’ve engineered our virgin Polypropylene Lids and thermoplastic elastomer gasket specifically for high chemical resistance and the ability to keep your valuable terpenes in the product, where they belong.

Your choice of packaging is especially important when considering terpene-rich concentrates, given that a low quality jar will allow the vast majority of volatile organic compounds to degrade in only a few weeks. This rapid terpene loss renders your product lower quality than intended, or worse, unusable, contributing to the cannabis industry’s waste problem.

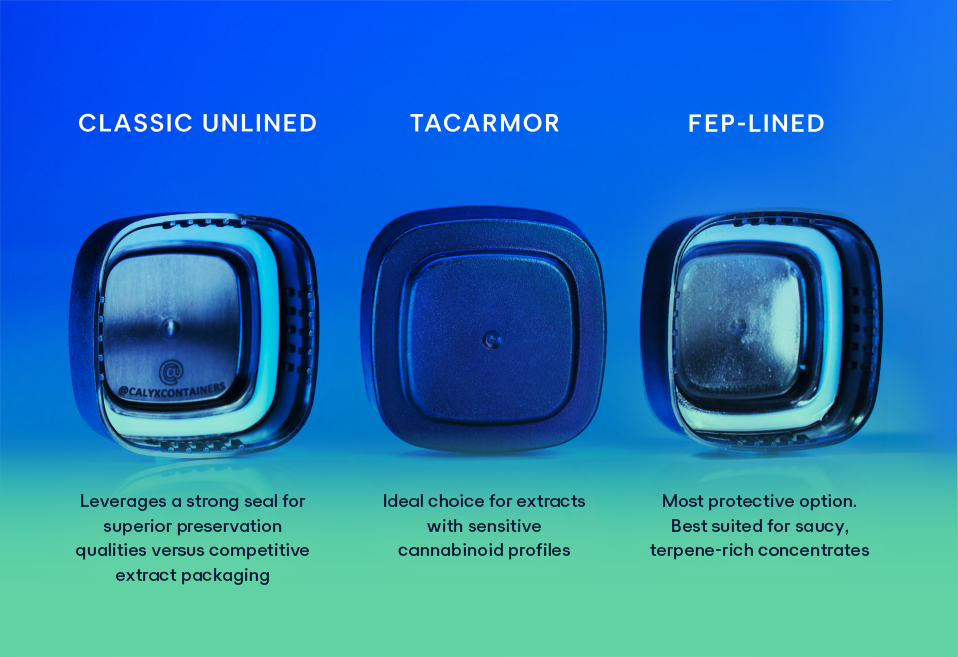

When you’re packing especially sensitive concentrates and being mindful of your brand’s environmental impact, you may be looking for even more protection than the secondary seal in Calyx’s Classic Unlined Concentrate Lids. We empower you to take product preservation and sustainability a step further with our enhanced Concentrate Performance Tiers: TACarmor Lids and FEP Liner. These technologies and materials offer significant benefits in cannabinoid and terpene preservation, ensuring that every gram is in the right condition to be enjoyed by your consumers.

What High Performance Packaging Means for Your Operation

Cannabis shelf life is under researched and misunderstood, with Best By dates being directed by little more than arbitrary one year timelines due to a lack of any accurate degradation framework. To put it simply, where other types of organic products spoil, cannabis products experience a chemical change.

What makes cannabis unique from other agricultural products is its wide range of cannabinoid and terpene profiles, which vary from strain to strain, and plant to plant. Even minor changes in THC-A:CBD ratios or THC:CBN ratios can have a noticeable impact on consumption effects, and these ratios are constantly changing from growth to cure to storage. Even though Calyx doesn’t decide how Best By dates are determined (yet), our packaging is designed to keep your cannabis products in their current state for as long as you need it.

Low performance packaging can be detrimental for your products, consumers, bottom line, and our planet. Rapid moisture and terpene loss can impact your products’ reputation, leading to lower sales, even greater levels of waste in the form of unsold products, and lowered consumer satisfaction.

Traditional Cannabis Packaging is Repurposed for Acceptability, not Optimized for Cannabis

The most common cannabis packaging in the industry is not cannabis packaging at all, but simply old format plastic products that have been cheaply repurposed for the cannabis industry. Pop Tops and Palm + Turn containers only provide a loose barrier against the environment, and products packed inside them are susceptible to minor changes in heat, humidity, and UV light.

The vast majority of these packages are also sourced from international supply chains, which are associated with a high degree of defects, deficiencies, and contamination. That’s waste in the form of unusable packaging, not to mention the quality loss and potential spoilage of the flower, edibles, or other cannabis products packed inside.

The low performance and high risk of these unsustainable packaging products introduce unnecessary quality and sustainability risks to your operation, and are generally unsuitable for the safe storage of high value, sensitive cannabis products.

Rapid moisture and terpene loss can impact your products’ reputation, leading to lower sales, waste in the form of unsold products, and lowered consumer satisfaction. Calyx Drams and Concentrates offer up to 6.5x greater resistance to environmental changes with our proprietary gasket sealing system, keeping your products in ideal conditions–no sustainability headaches required.

Novel, Retrofitted Packaging Solutions Improve Performance at a High Cost

As the cannabis industry has matured, new players have entered the packaging space in an effort to improve the performance of traditional packaging solutions. Alternative technology is often paired with traditional formats to target cannabis products, but this pairing doesn’t always offer a complete solution.

Hermetically Sealed Modified Atmosphere Packaging

Solutions like hermetically sealed Modified Atmosphere Packaging (MAP) typically utilize nitrogen flushing to eliminate reactive oxygen from cannabis. Originally designed for medical supplies and sensitive electronics, this technology is excellent at preserving a product’s integrity throughout most of the value chain, but not well-suited for cannabis. Hermetically sealed packages cannot be resealed once opened, forcing consumers to transfer the product to alternative packaging immediately after purchase and effectively rendering them single-use. This limitation, combined with the high cost and complexity of the necessary equipment and materials for large-scale operations, makes MAP solutions impractical and unsustainable for most cannabis producers and cultivators.

While hermetically sealed packaging offers the strongest possible seal according to ASTM standards, its protective qualities are lost once the consumer opens the package. After opening, the product degrades and contributes to the cannabis industry’s waste problem. Additionally, the energy and resources required for this type of packaging are excessive given that its benefits diminish after the initial use.

Hermetically sealed packages cannot be resealed once opened, forcing consumers to transfer the product to alternative packaging immediately after purchase and effectively rendering them single-use.

In contrast, Calyx Containers maintain their protective qualities both before and after the package is opened by the consumer. Our innovative secondary gasket seal ensures peak performance for up to sixteen openings, providing consistent protection and a better overall experience for the end user.

Biophotonic and UV-Blocking Glass

Other solutions aim to aggressively optimize materials, such as biophotonic or “light proof” UV-blocking glass, at an exorbitant cost with minimal Shelf Life benefit, while still relying on international supply chains that increase packaging and product risk.

UV rays are known to negatively impact the cannabinoid Shelf Life, but how exactly does this mechanism work?

- While many believe that UV Light incentivizes cannabinoid degradation, it actually causes cannabinoid fracture.

- This means that high exposure to UV light breaks desirable compounds into smaller, useless pieces, removing them completely from the product. Even though this is an enemy of proper cannabis storage, it occurs at a very low rate.

- Another industry player, Orange Photonics, performed a study on the impact of UV light exposure on cannabis flower, and found that detrimental cannabinoid fracturing occurs in an excessively high-UV environment, far beyond anything a product would naturally experience.

40 hours of continuous, high-strength UV exposure caused cannabinoid concentration to drop only a few percentage points, while the average packaged product will likely experience <1% of this type of UV exposure across its entire shelf-life.

While UV mitigation is one component of proper cannabis storage, it is a lesser risk than oxygen and terpene control and is typically not worth the high costs and questionable manufacturing associated with these specialized glass products.

Though Calyx Concentrates don’t contain UV-blocking glass, our container’s wide shape and opaque lids naturally limit exposure, even in harsh conditions. Additionally, both Calyx’s Clear and Opaque Plastic Drams offer high UV resistance through colorant and UV-blocking additives, keeping our bases covered.

While UV mitigation is one component of proper cannabis storage, it is a lesser risk than oxygen and terpene control and is typically not worth the high costs and questionable manufacturing associated with these specialized glass products.

How Calyx Protects Cannabis Differently

When we say sustainability is multi-dimensional, we mean it. Many organizations benchmark against sustainability goals through careful carbon emission comparisons and Life Cycle Analyses. We do that. Other organizations carefully curate the materials of their product line to have the lowest possible impact on the environment while mitigating product spoilage and waste. We do that, too.

A sustainable operation first needs to be a profitable one, and this is the niche that Calyx has carved out in the cannabis industry: keeping cannabis in top shape is our business. Alongside the superior performance, materials, and environmental impact Calyx offers over competitive options, Calyx Containers deliver true product differentiation against a sea of generic packaging to keep your business, and the planet, in the green.