Demystifying Degradation + Cannabis Shelf Life

From regulatory challenges to nuanced testing methodologies, we’re shedding light on the evolving landscape of cannabis storage and preservation, empowering brands to make informed decisions and ensuring consumers receive the highest quality products. Dive into the world of cannabinoids, terpenes, and packaging innovations to gain insight into measuring cannabis shelf life, freshness, and potency.

Stay in touch!

Join our email list to receive Calyx content & product updates.

By Calyx Containers in Cannabis Packaging

Warning: High Potency Article Ahead

Buckle up for an immersive read and reach out to our team at info@calyxcontainers.com if you have any questions or feedback about this material. We value your input and are committed to making Cannabis Science more accessible and relevant to you.

Article Highlights

- Current regulations lack precise shelf life determinations for cannabis, often relying on arbitrary dating.

- Product "spoilage" may actually represent transformation, altering effects without spoiling the product.

- We recommend multi-phase testing for a more accurate assessment of product effects over time and to address industry waste.

- Understanding cannabis analytes like Δ9-THC, CBD-A, and terpenes empowers informed decisions on packaging and performance.

Navigating Cannabis Shelf Life + Quality

Cannabis is a complex plant, containing over 150 Terpenes, 100 unique Cannabinoids, and still many other Volatile and Cannflavin Compounds. Each of these Cannabis Constituents offers individual and entourage effects for the consumer, which can change as compounds degrade or transform based on their environmental and storage conditions.

The lack of a universally accepted method for establishing the rate of Cannabis degradation makes it extremely difficult for producers and retailers to know how long they have to sell high quality product, and what conditions to store it in until final sale. Ambiguity in Cannabis Shelf Life poses a particular concern for medical consumers, who often purchase products due to the Cannabinoid and Terpene Profile present at the time of initial testing. Meanwhile, these characteristics can change drastically in just a few short weeks of storage.

With all this complexity, how can you determine how fresh your product really is, or if it’s still the product you intended to purchase?

Spoiled or Transformed: What Does Cannabis Degradation Really Mean?

Spoilage, degradation, decomposition, and contamination are familiar terms in nearly every industry involving an organic product that will eventually become unfit for consumption.

Most people understand the importance of checking expiration dates on food, medicine, and cosmetics to make sure that the quality of the product is the same (or similar) to the quality at the time of packaging. Labels such as “use before,” “sell by,” and “expires on” all give indication to the amount of time a product can stay in its original packaging before it is no longer at optimal quality. However, even these terms carry a degree of obscurity, and the FDA has become more outspoken that many of these labels are not determined by an exact science.

To date, there is no accurate Shelf Life associated with cannabis material, and many states will regulate stored cannabis products with an arbitrary date. This results in many products being unnecessarily discarded, or discarded too late, which contributes to waste and environmental impact driven by the cannabis industry. While there are certainly some characteristics that make a cannabis product unfit for sale, like the presence of unsafe levels of heavy metals, coliforms, and pesticides, many secondary degradation products result in an effect change, rather than a spoilage.

To date, there is no accurate Shelf Life associated with cannabis material, and many states will regulate stored cannabis products with an arbitrary date.

The Curious Case of Δ9-THC Degradation

At its most plain, the process of degradation is characterized as a reduction in the complexity of a chemical compound. Heat, light, and air constantly work together to force complex molecules into a simpler, entropically favorable structure.

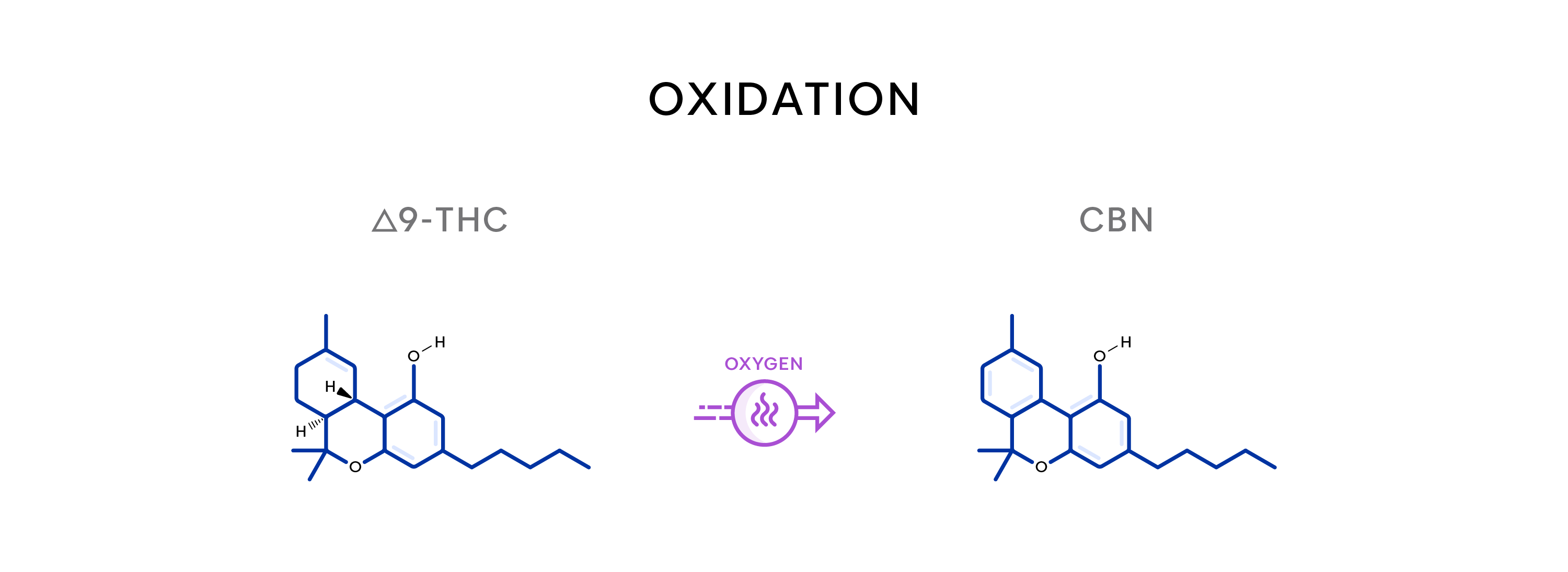

For cannabis, this means the transition of “desirable” compounds into “undesirable” compounds. One prime example of this is the degradation of Δ9-THC into CBN.

This transformation happens to be one of the first entourage effects discovered, and is of primary concern when it comes to storing cannabis. If you’ve ever consumed a cannabis product that’s sat around on a sunny windowsill, or been tucked away in a drawer for a year or two, you may have noticed that it had a significant drowsy effect. This is directly caused by CBN in tandem with Δ9-THC. While drowsiness may not always be desired, it's an effect nonetheless. Interestingly, many cannabis products are formulated precisely to induce drowsiness.

So, does a spike in CBN levels render a product unfit?

Should the product be considered waste and discarded, or a new product to be re-labelled and sold?

The curious case of CBN offers us just one example of how challenging it is to accurately determine a cannabis product’s shelf life, especially when testing is only performed upon what’s initially packaged. Multi-phase testing conducted at key intervals is one way to obtain a better understanding of where a product is in its degradation process, as opposed to when a product has reached its expiration date based on initial test results.

Calyx Takes A Nuanced Approach to Quantifying Cannabis Degradation and Shelf Life

Many methods for quantifying Shelf Life have been explored–Moisture Content, THC or CBD Concentration, Terpene Concentration, Microbial Contamination–without industry-wide consensus. Since no single method of analysis is reliable or agreed upon, we use a wide lens to understand what compounds are degrading, the rate at which they degrade, and the subsequent concentration of secondary and undesirable degradation products.

In our view, meaningful Shelf Life Testing considers a wide variety of Major and Minor Cannabinoids, as well as Terpene Concentration and Safety Testing.

Multi-phase testing conducted at key intervals is one way to obtain a better understanding of where a product is in its degradation process, as opposed to when a product has reached its expiration date based on initial test results.

Cannabis Analyte Overview

Total Active Cannabinoids (TAC)

TAC, or Total Active Cannabinoids, is the sum of all Major and Minor Cannabinoids present in a sample. This measure offers a high-level, if imprecise, view of what types of degradation are occurring.

While it would seem that TAC should always decrease over time, the reaction is highly dependent on the characteristics of the cannabis product being tested. Full spectrum products like live rosin and hash which have been exposed to minimal heat may experience an increase in TAC due to the continual synthesis of new Cannabinoids from Cannabinoid pre-cursors (such as CBG-A). In products with very low concentrations of Cannabinoid pre-cursors, we can expect the rate of degradation to exceed the rate of natural synthesis.

On the other hand, distilled products, or products like shatter, RSO, and BHO that have experienced greater heat or filtration, are less likely to experience natural Cannabinoid synthesis, and will overwhelmingly exhibit a decrease in TAC over time.

THC-A

THC-A concentration is a key measure in determining the rate of degradation of a Cannabis product. This is a compound that most producers are familiar with, but is often confused or combined with Δ9-THC at the consumer level. Much like TAC, THC-A concentration can increase or decrease with time depending on the characteristics of a cannabis product.

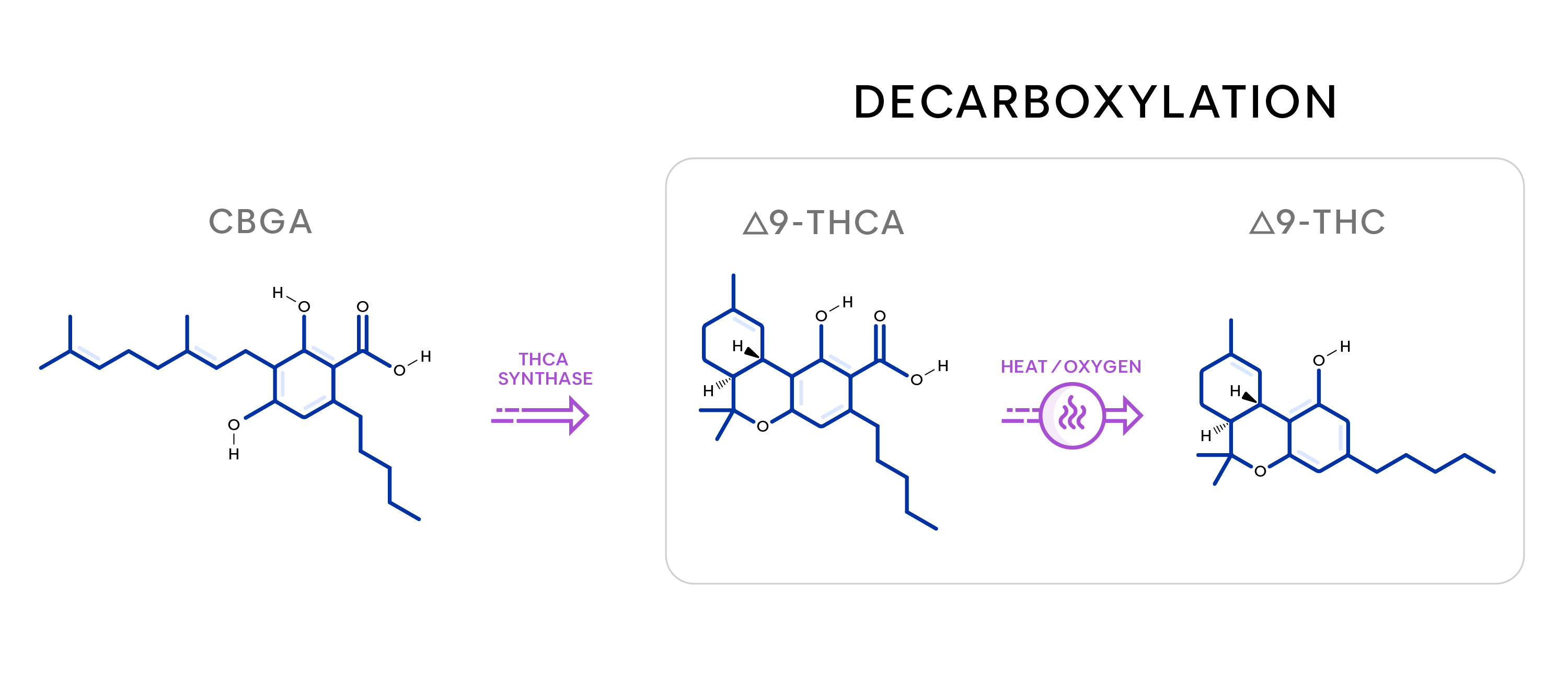

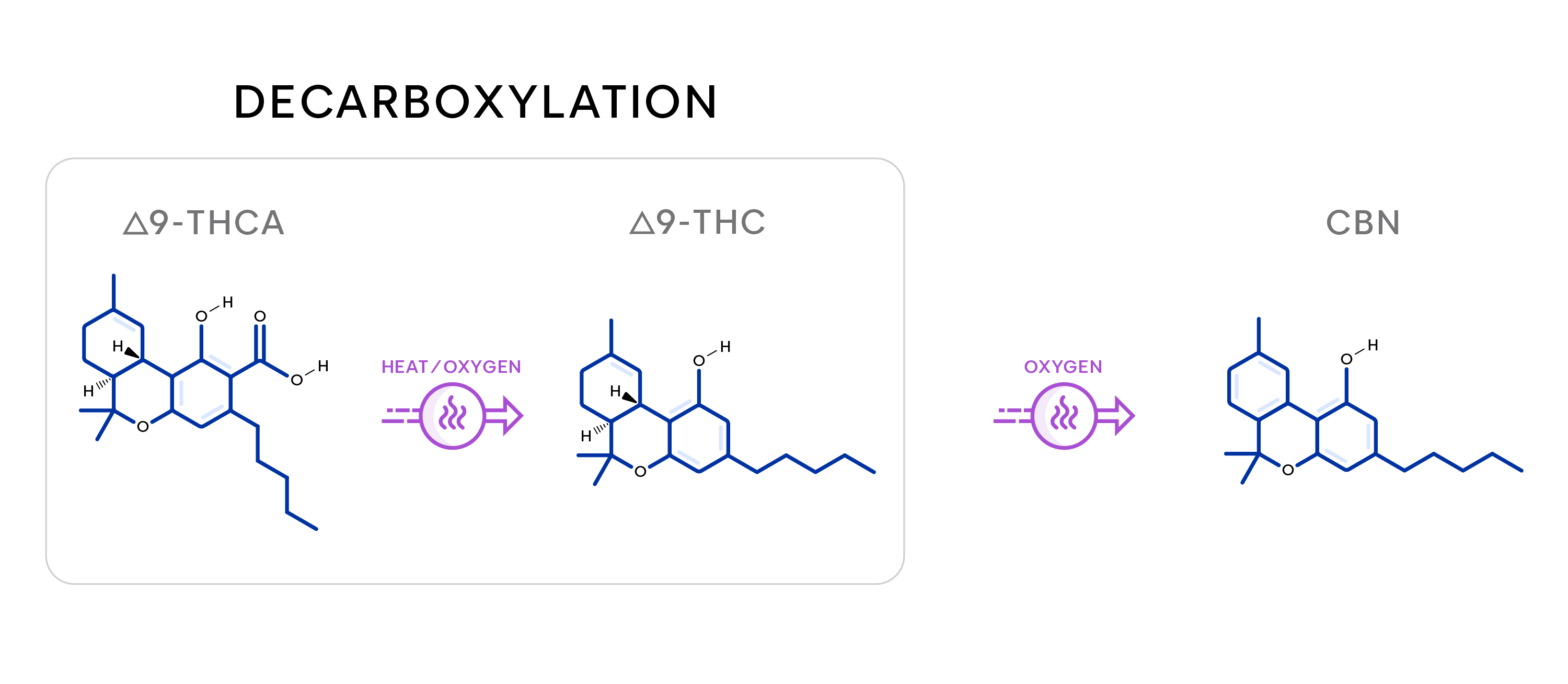

THC-A concentration can change by two different reaction pathways: Synthesis and Decarboxylation.

When conditions are favorable, CBG-A will naturally synthesize new THC-A, even in a packaging environment! This is a mostly beneficial reaction, with increasing THC-A allowing for greater overall potency of the final product, even after long-term storage.

However, the secondary decarboxylation of THC-A indicates a potential for less desirable outcomes. While decarboxylation is typically known to be a heat-mediated reaction, it will also occur in room temperature and cold temperature environments as a spontaneous reaction. Oxygen is the true catalyst for decarboxylation, so minimizing Oxygen Transfer in a packaging environment is key to maintaining (and potentially increasing) THC-A concentration after packaging.

Δ9-THC

The concentration of THC, and subsequent formation of CBN, is an ideal indicator for the overall quality of a packaged Cannabis product. The relative simplicity of this reaction pathway allows for accurate insights into the product’s exposure to heat and oxygen. Since this is a balanced, two-step reaction, a decrease in THC inevitably results in an increase in CBN, a generally undesirable degradation product.

Both of these reaction steps are mediated by oxygen exposure, so high rates of change in these compounds indicate a high rate of Oxygen Transmission in the packaging.

CBN

The isomerization of THC is a one-step process that results in the single degradation product of CBN. Under normal storage conditions, THC will almost exclusively degrade into CBN, making it another ideal target for investigation.

With this knowledge, we can say that increases in CBN concentration over time indicate high rates of heat and oxygen exposure within a cannabis package.

While this can be an ideal target, the extremely low starting concentrations of CBN, as well as the relatively small changes due to degradation over shorter time periods, can make it difficult to track accurately. Analytical methods outside of High Pressure Liquid Chromatography/Mass Spectrometer will often have a large degree of variance when tracking the concentration of this compound, so we’d recommend you pull degradation insights from a combined data tracking both THC and CBN levels.

CBD-A

The concentration of CBD-A is another indicator that good storage conditions are being met, and that obtained shelf life data is accurate. While not a particularly good test target for tracking degradation, CBD-A concentration can act as a Positive Control, where Cannabis material containing CBG-A should exhibit a small, but consistent, increase in CBD-A over time.

If CBD-A concentration is falling or staying the same under normal storage conditions, the confidence in other obtained analytical data is low.

CBD

Unlike THC synthesis, the process of decarboxylation converting CBD-A into CBD demands considerably more energy and primarily happens due to direct exposure to heat.

In normal storage conditions, any increase in CBD concentration should be negligible. In this way, CBD concentration can effectively act as a Negative Control, where no identified rate of change indicates confidence in other obtained data.

If CBD concentration is increasing or decreasing at a significant rate, it can mean that obtained analytical data is inaccurate, or that proper storage conditions are not being met for the testing period.

Terpenes

While the evidence for the significant medical benefits of terpenes is still being established, Terpene concentration and retention is of high concern for many producers and consumers.

Terpene Retention presents what may be the greatest challenge in packaging cannabis products due to Terpenes’ volatility and solvent properties. Unlike other compounds, Terpenes show minimal degradation from oxygen, heat, and UV light. Their preservation primarily hinges on a package’s materials and seal integrity.

That said, Terpene Retention is only one factor which dictates the quality of packaged Cannabis products, and must be balanced with the retention of other key Cannabis constituents.

Unlike other compounds, Terpenes show minimal degradation from oxygen, heat, and UV light. Their preservation primarily hinges on a package’s materials and seal integrity.

Let's Play That Back

In the ever-evolving landscape of cannabis products, understanding degradation is crucial for both producers and consumers. Delving into the complexities of cannabis degradation offers insights into the transformation of cannabis analytes and the challenges of preserving terpenes. By implementing nuanced testing methods, like those employed by Calyx, brands can ensure product quality and provide accurate information to consumers. As the industry matures, a deeper understanding of degradation will be indispensable for maintaining product integrity and meeting consumer expectations.

Choose a packaging provider who does their due diligence on cannabis preservation science. Request samples and experience the quality for yourself.