A New Era of Global Supply Chain Uncertainty

In recent years, cannabis operators have faced mounting pressures that have exposed the fragility of global supply chains. From container shortages and port congestion to Red Sea shipping blockages and U.S.–China trade tensions, importing packaging has become unpredictable and costly.

How Calyx Built a U.S.-Based Solution

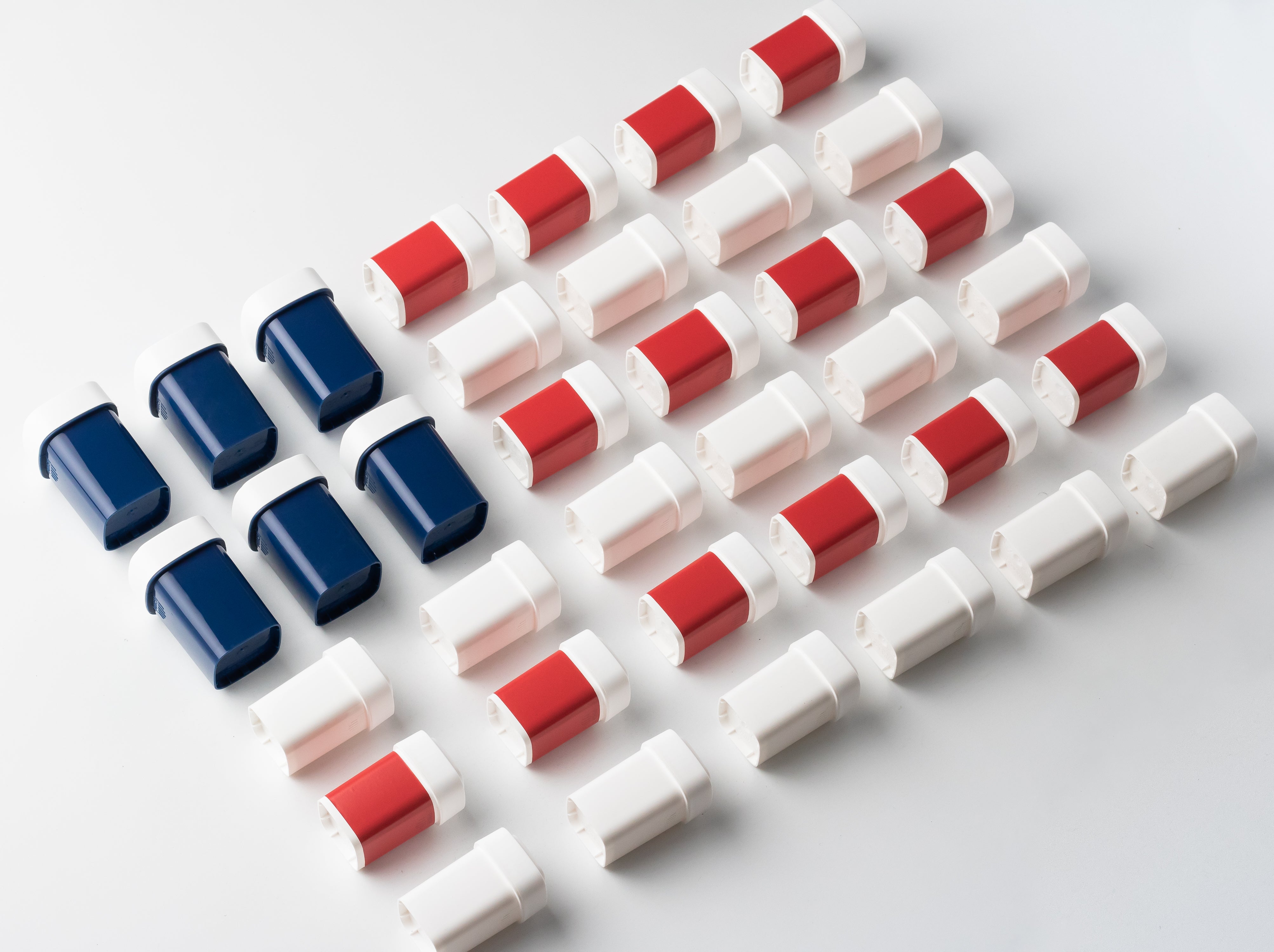

While much of the packaging industry continues to rely on outsourced manufacturing and freight-forwarded materials, Calyx Containers has taken a different path: investing in vertical integration right here in the U.S. Calyx operates domestic injection molding for its rigid container line—most notably the Calyx Dram, a container specifically engineered for cannabis flower, pre-rolls, and infused products. This means the company controls production timelines, material consistency, and quality assurance from start to finish.

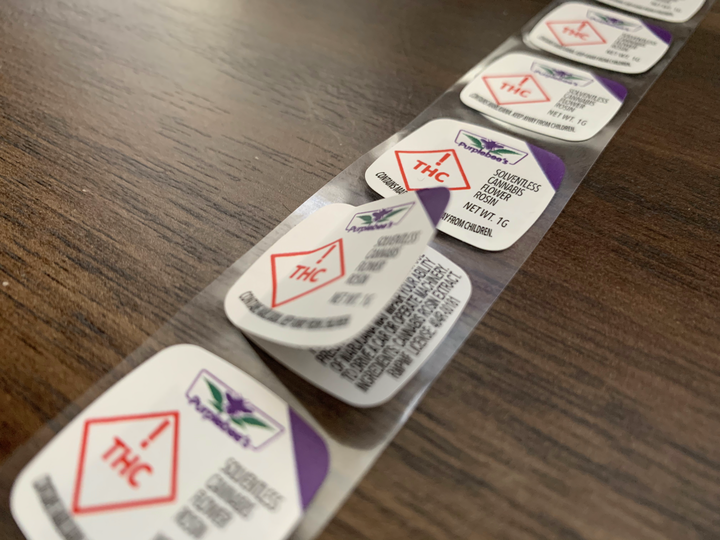

Beyond molding, Calyx has also brought label printing in-house, offering custom branding solutions with faster turnarounds and fewer minimums. By owning the full packaging workflow—from base component to final brand presentation—Calyx eliminates many of the supply chain gaps that plague the industry. This localized, vertically integrated model is rare in the cannabis packaging space—and it’s exactly what operators need in uncertain times.

The Dram: A Category-Defining Container

The Calyx Dram has become one of the most recognized and reliable cannabis packaging formats in the industry. It’s not a stock container repurposed for flower—it was built for cannabis, from the ground up. With a tamper-evident form factor, durable materials, and airtight locking system, the dram maintains product freshness and potency, even during long distribution cycles. It’s compatible with automation and ideal for fast-moving production environments—helping businesses scale efficiently.

While cheaper options may exist on paper, few match the Dram’s balance of compliance, usability, brand aesthetics, and logistical performance.

Long-Term Partnerships, Not Just Short-Term Pricing

Calyx’s vertically integrated model allows for consistent, predictable fulfillment across the U.S.—but the company has gone a step further by introducing multi-year pricing agreements for businesses planning 12 to 36 months ahead.

These contracts help MSOs, processors, and independent operators lock in pricing, secure inventory, and streamline planning across SKUs and regions. In a time of economic unpredictability, Calyx’s approach gives buyers back a critical advantage: control. And because every part of the product—container and label—is sourced and produced in the U.S., customers benefit from faster reorders, tighter quality assurance, and fewer touchpoints.

A Smarter Way to Source Cannabis Packaging

In a global market defined by risk, volatility, and rising costs, Calyx Containers offers something different: packaging that’s designed for cannabis, made in the USA, priced to support growth, and delivered without tariff complications. With vertically integrated production, in-house labeling, and flexible partnership structures, Calyx enables cannabis operators to take control of their packaging strategy—and their supply chain.

Calyx’s reduced pricing and U.S.-based manufacturing are already helping cannabis brands streamline operations and scale smarter. Learn how your business can benefit from tariff-free, domestically made cannabis packaging—now with flexible pricing built for the road ahead.