In today’s fast-moving cannabis market, speed and efficiency can make or break your brand. Whether you’re a cultivator getting fresh flower packaged for dispensary shelves, an edibles producer preparing for a product launch, or a multi-state operator scaling SKUs, delays and rising costs can quickly erode your margins.

One of the biggest factors impacting both speed-to-market and profitability? Where your cannabis packaging is made.

While many companies still source packaging overseas to chase lower unit costs, the hidden expenses—tariffs, freight delays, unpredictable lead times, and inconsistent quality—often outweigh the initial savings. For brands looking to protect their bottom line and keep shelves stocked, domestic cannabis packaging is becoming the clear solution.

At Calyx Containers, our Salt Lake City, Utah-based facility manufactures cannabis packaging designed specifically for this industry, helping brands eliminate unnecessary costs and get their products to market faster. Here’s why keeping your packaging local pays off.

The True Cost of Overseas Cannabis Packaging

At first glance, sourcing packaging internationally—whether jars, drams, pouches, or tubes—can seem cost-effective. Overseas suppliers often quote lower per-unit pricing, especially on large volume orders. But those savings are rarely what they seem.

Here’s where the costs pile up:

- Freight and Customs Delays: Ocean freight alone can take 6–8 weeks, not including unpredictable customs holds. One delay can disrupt production timelines and strain retail commitments.

- Tariffs and Surcharges: Cannabis brands importing packaging often face unexpected tariffs and shipping fees, cutting into already tight margins.

- Inconsistent Quality: Overseas factories may operate with variable standards, resulting in off-spec product or failures in CR certification testing—problems that can lead to rework or recalls.

- Inventory Challenges: Long lead times force brands to over-order, tying up cash in warehouse stock and creating storage headaches.

When every week of delay means missed sales and every ounce of waste impacts profits, the “cheaper” option quickly becomes the costlier one.

The Advantages of Domestic Cannabis Packaging

By choosing U.S.-manufactured packaging and labels, cannabis brands gain a competitive edge in both speed and cost control. At Calyx Containers, we’ve built our Salt Lake City facility to deliver high-performance packaging and labels without the headaches of overseas sourcing.

Here’s how domestic packaging saves you time and money:

1. Faster Lead Times

- Get packaging in weeks, not months.

- Respond quickly to seasonal surges, strain-specific launches, or regulatory changes without overstocking.

- Launch products faster, keeping your retail partners and customers happy.

2. No Tariffs or International Freight Costs

- Eliminate unexpected duties, taxes, and fluctuating shipping surcharges.

- Save on ocean and air freight—significant cost factors that eat into profits.

3. Consistent, Reliable Quality

- Every Calyx container is manufactured under strict QC standards, ensuring consistent dimensions, seals, and CR performance.

- Avoid costly recalls or compliance issues due to failed certification or poor construction.

4. Better Inventory Control

- Shorter lead times mean you can order what you need, when you need it.

- Reduce warehousing costs and free up cash flow by avoiding bloated inventory.

Affordable Packaging Without Compromise

“Affordable” in cannabis packaging often gets confused with “cheap”—thin plastics, generic jars, or poorly fitting lids that fail to protect your product.

At Calyx Containers, affordable packaging means cost-efficient production and materials that protect your flower, concentrates, or edibles without cutting corners:

- Recyclable Materials: Our Drams are made with 100% recyclable #5 polypropylene, balancing sustainability with performance.

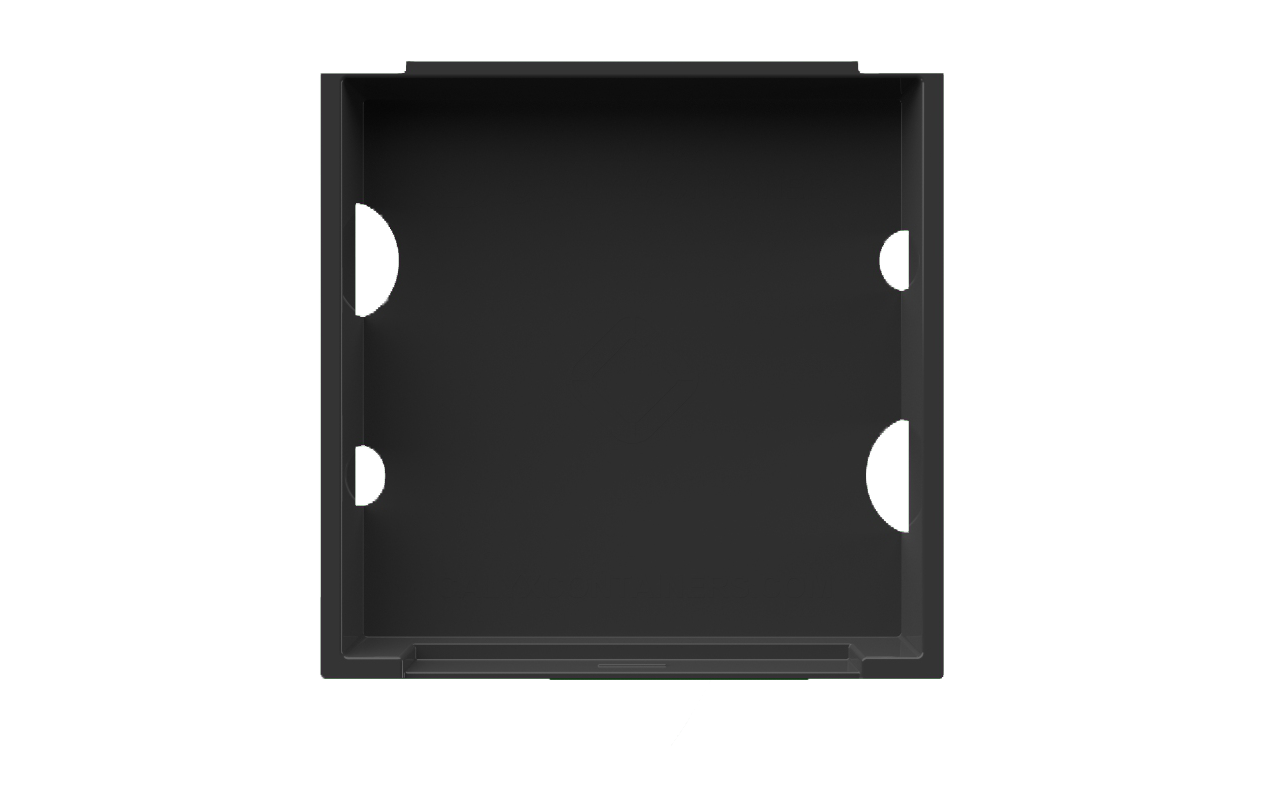

- Optimized Design: Stackable, space-saving shapes help lower storage and shipping costs.

- Durability and Protection: UV-blocking additives and airtight gasket seals keep products fresh, potent, and compliant.

When you combine domestic production with smart design and recyclable materials, you get packaging that performs—and saves money long-term by reducing product loss and waste.

Real-World Impact: Speed and Scale for Every Operator

From start-ups to multi-state operators, every cannabis brand can benefit from the agility of domestic production. Here’s how Calyx helps:

- For Cultivators: Get Calyx Cure, Drams, or Flexible Packaging (FlexPack) pouches delivered quickly so fresh flower reaches shelves at peak quality.

- For Edibles Producers: Child-resistant, airtight containers help you comply with state laws while extending shelf life.

- For Growing Brands: Digital label printing and small-batch pouch runs help you scale SKUs without over-committing on inventory.

Our Salt Lake City production facility gives brands the speed and reliability they need to meet deadlines, maintain quality, and grow profitably.

Why Partner with Calyx for Domestic Cannabis Packaging?

- U.S.-Based Manufacturing: Faster turnaround times, no tariffs, no overseas delays.

- CR-Certified Options: From Drams to FlexPack, every container can be configured to meet CR standards.

- Affordable and Sustainable: 100% recyclable materials and space-efficient designs that reduce total costs.

- Full Branding Support: From custom labels (CalyxFX) to printed pouches, we help your packaging work as hard as your product.

Final Thoughts

In cannabis, every day counts—and every gram matters. If your packaging supply chain is holding you back with high costs, long waits, or inconsistent quality, it’s time to make the switch.

By sourcing domestic cannabis packaging from Calyx Containers, you’ll save time, protect your margins, and get high-quality, compliant packaging that supports your growth at every stage.

👉 Ready to cut costs and get to market faster? Explore our full line of U.S.-made cannabis packaging & label solutions.