(Short answer: it creates a self-regulating micro-climate.)

Why it outperforms conventional bags

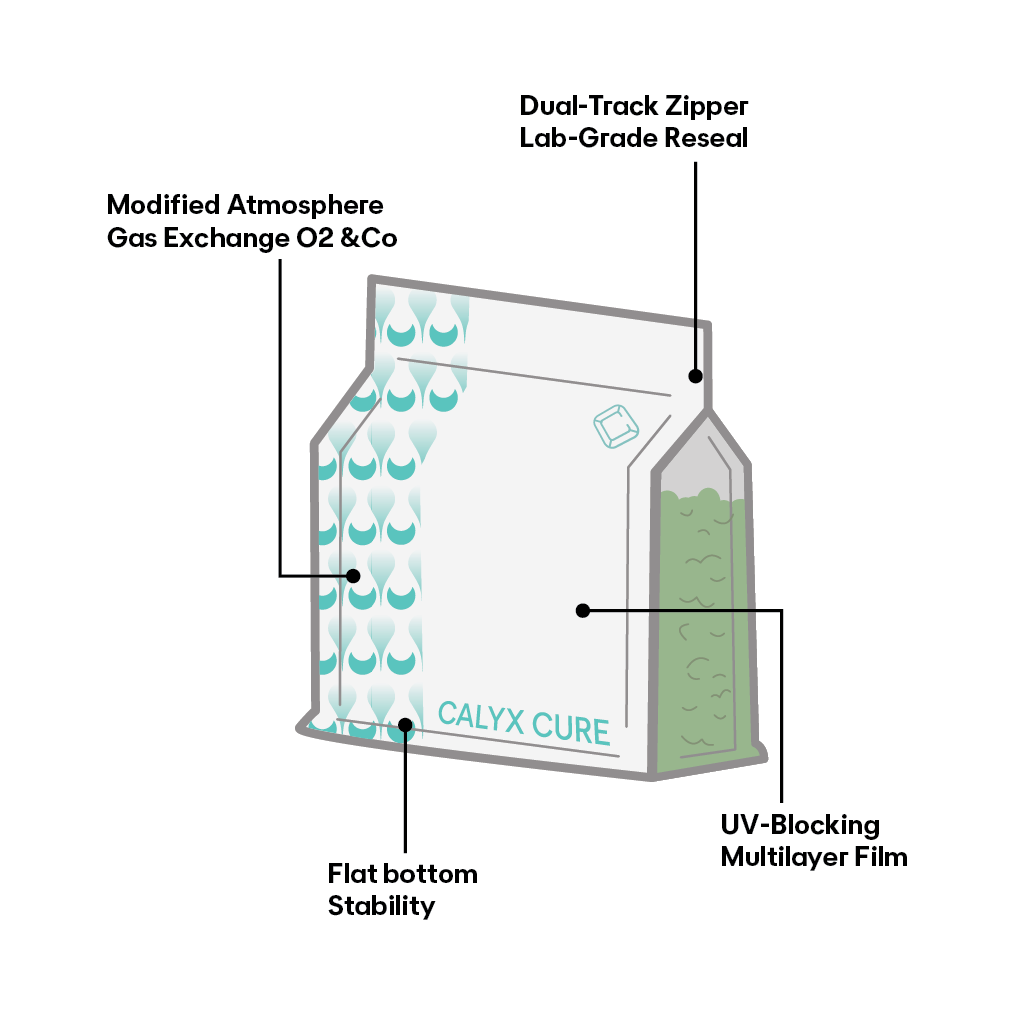

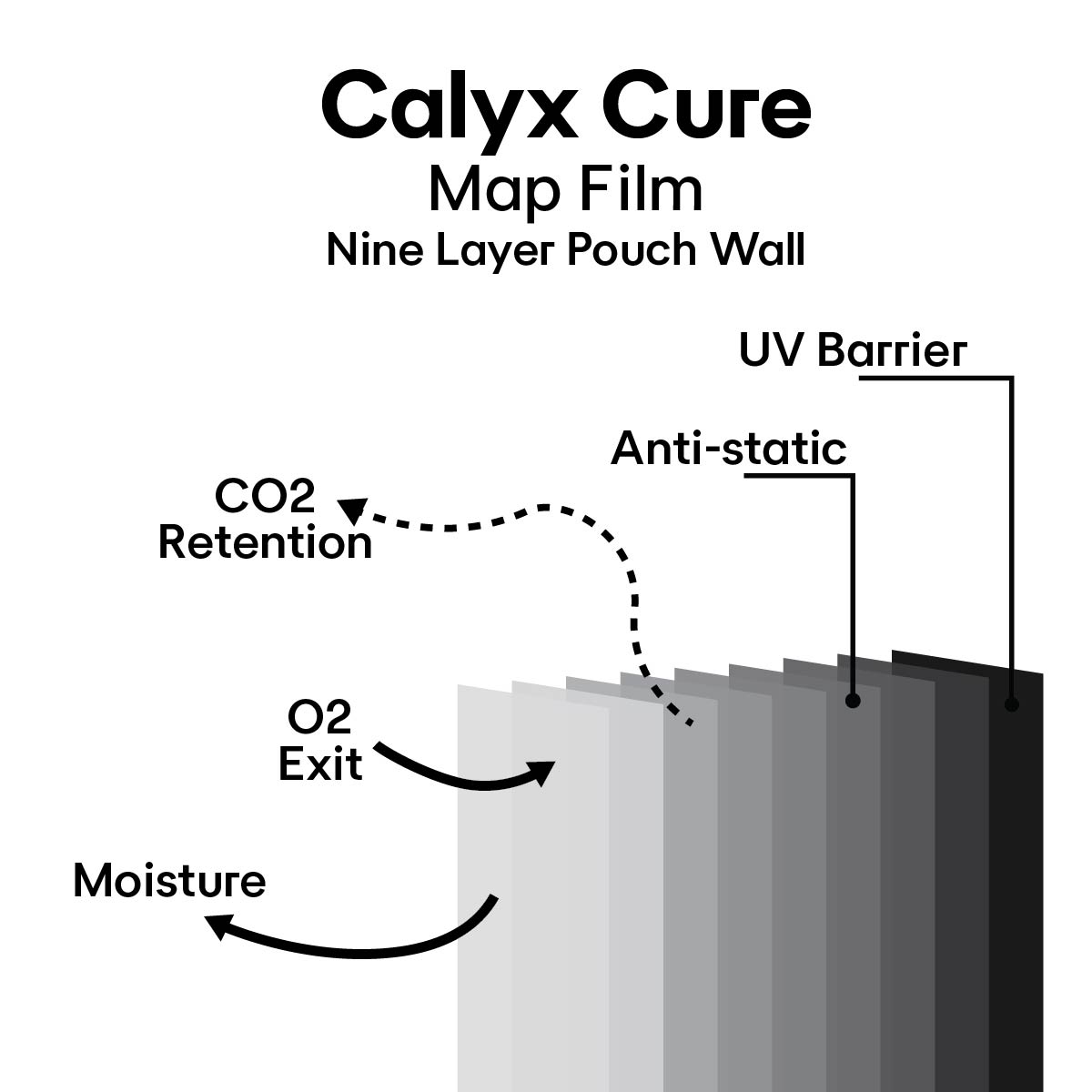

- The nine-layer film fine-tunes O₂ and H₂O vapor exchange while venting excess CO₂, keeping buds in the ideal range.

- Built-in UV, oxygen, and odor barriers slow oxidation and terpene loss far beyond a single-layer poly bag.

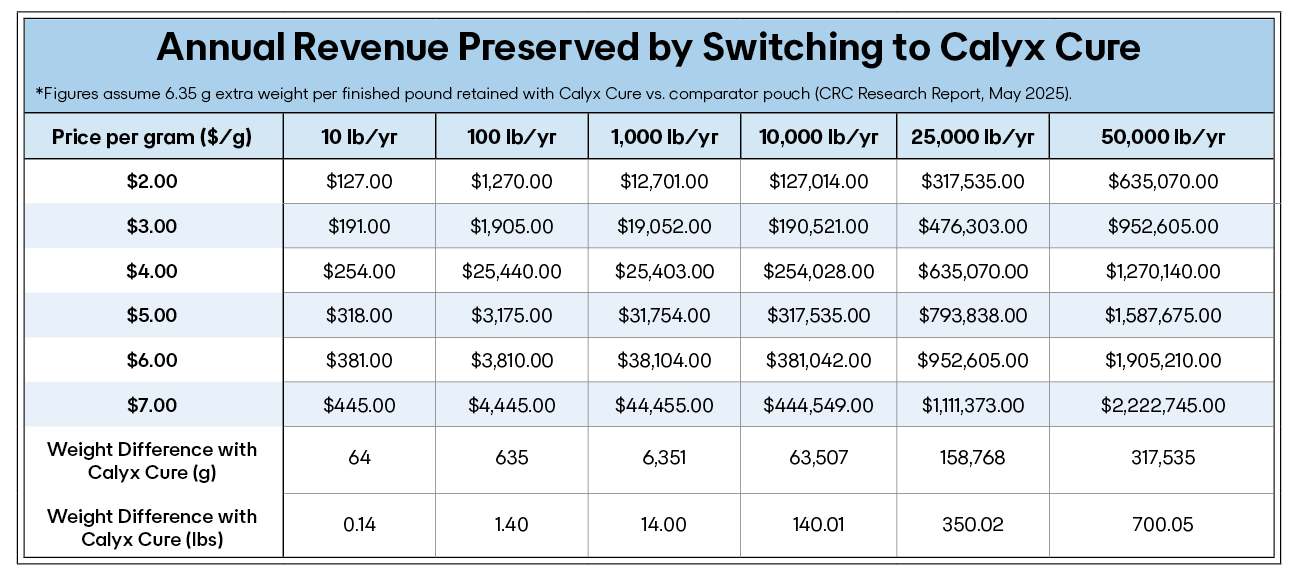

- Controlled moisture prevents “shrink-age,” so grams stay grams.

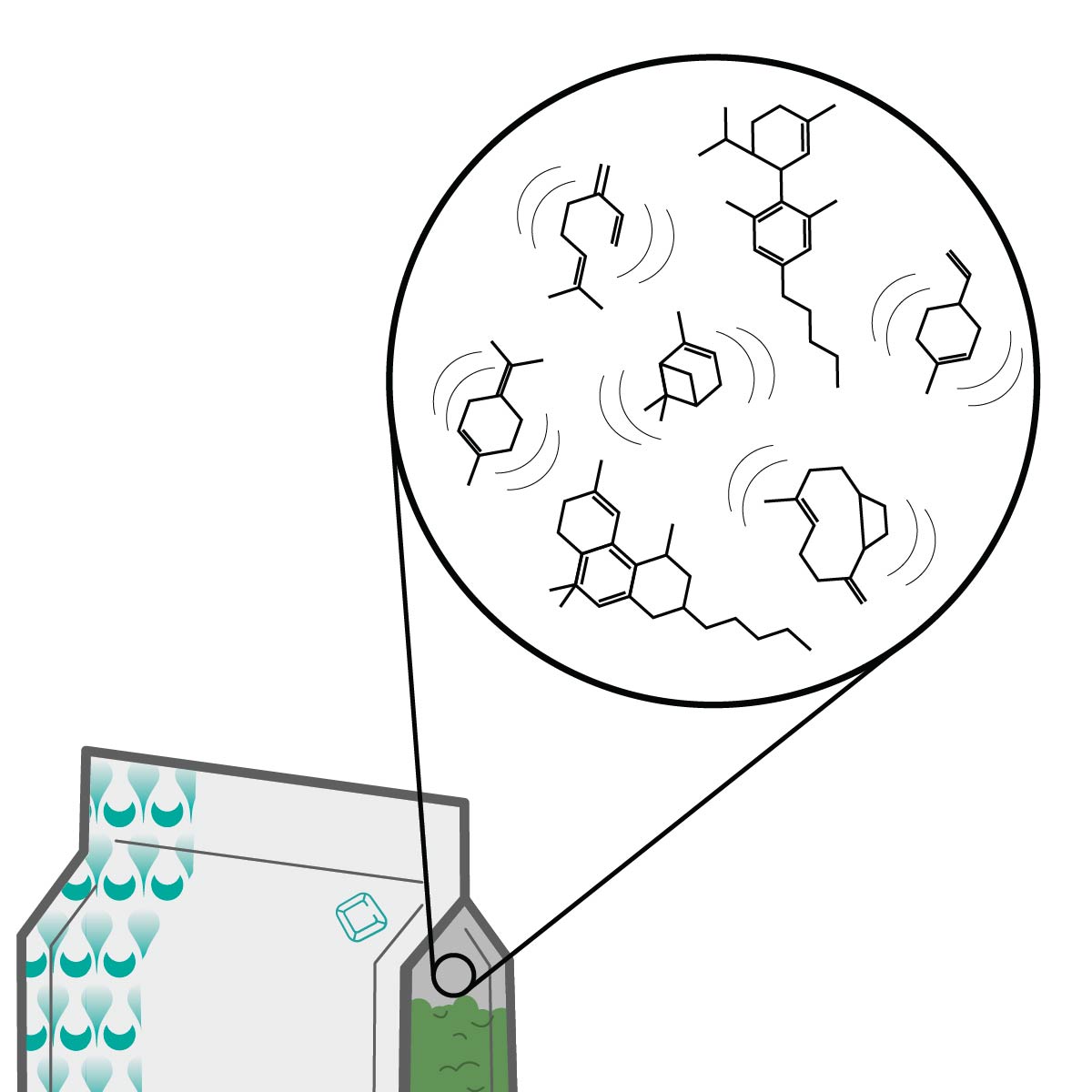

- Volatile aromatics remain sealed inside, preserving potency and aroma.

- Stops trichomes from clinging to the pouch walls, keeping cannabinoids where they belong—on the flower.

Bottom line

Calyx Cure is essentially a miniature controlled-atmosphere chamber: it lets cannabis breathe just enough to stay balanced while blocking everything that degrades quality. The result is fresher, more aromatic, full-weight flower long after ordinary plastic bags have gone stale.

(Short answer: absolutely.)

How it works

- The pouch includes a second tear notch so you can reseal, heat-seal again, and still have an easy-open tab.

- Our upgraded dual track zipper gives a firm, tactile snap each time you close it, locking in aroma and moisture between uses—no extra clips needed.

- After you break the first seal, you can re-purge the headspace and apply a new heat seal (home heat sealers work great). Open it again when you’re ready, then rely on the zipper for daily access.

Tip for best results

For long-term storage, heat-seal the pouch again; for short-term reuse, the zipper alone maintains the pouch’s modified atmosphere. Dispose of the pouch once both tear notches have been used.

(Short answer: not yet.)

Why not today?

- Each pouch is a nine-layer laminate that blends multiple polymers and active additives to lock in terpenes, regulate water activity, block oxygen, and shield UV—capabilities no single material can currently match.

- Because those layers can’t be separated in typical curbside systems, the film isn’t classified as recyclable or biodegradable.

What we’re doing about it

- Our materials team is actively testing next-gen resins that could deliver the same protection in a single, easily recyclable structure.

- We’re also piloting plant-based, home-compostable films for applications that tolerate shorter shelf-lives.

- Every new production run incorporates the latest advances we can source without compromising product freshness.

Until those breakthroughs are ready, please dispose of used pouches with regular household waste—and know that sustainability remains one of our core engineering goals.